A compactor is a machine that’s used to compress and compact materials and can be either portable or static.

A compactor is a machine that’s used to compress and compact materials and can be either portable or static.

The compaction process maximises the volume of weight of materials a skip/container can hold in order to reduce the frequency with which the skip/container needs to be emptied.

Compaction ratio rates vary depending on the type of waste being compacted, but can be up to as much as 6:1 compared to loose materials in a skip/container.

Compactors are most commonly used in recycling and waste management, but they can also be used in other industries such as construction, pharmaceuticals and food manufacturing.

In this blog post we’ll explore the many benefits of using static waste compactors for waste management.

What is a Static Compactor?

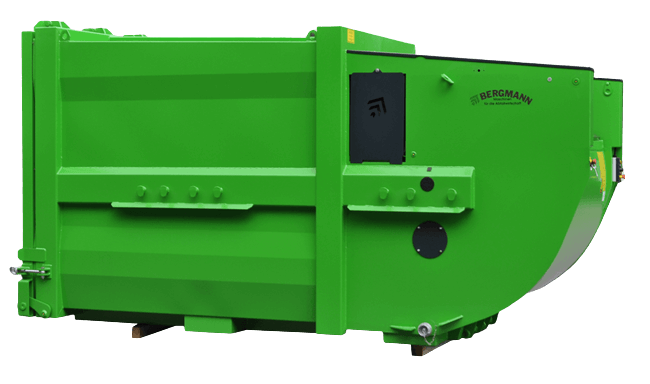

Static compactors are machines which are typically used on-site for compacting waste and recycling materials.

The waste/materials are fed into the compactor feed hopper, then a compaction ram pushes the contents of the hopper into the attached skip/container.

How it works

Unlike a portable compactor, with a static compactor the press unit is firmly attached to the ground and stays in one permanent location on site so only the skip/container needs to be removed and not the compactor itself. Transport containers are attached to the press, where the processed material is compacted. Once the transport container is full of waste material, it can be separated from the press and taken to waste disposal facilities.

An empty container can be then re-attached to the press. The stationary press and the transport containers are usually attached to each other manually by means of hand ratchets or with the use of a hydraulically controlled cylinder. The transport containers can be closed similarly, either manually or with a hydraulic locking device.

So an additional benefit of the static compactor is that when the roll on roll off vehicle collects the skip/container full of waste, an empty skip/container is delivered at the same time so there is a compactor permanently available for use. With a portable compactor, the compactor and container are one complete unit which would mean you would be without the use of the portable compactor whilst it’s taken away to be emptied.

Why Use Static Waste Compactors?

Some of the advantages of using a static waste compactor include:

- Reduced transportation costs

- Increased productivity

- Improved carbon footprint

- Versatility

Let’s look at these benefits in more detail.

Reduced transportation costs

The major benefit for installing a static compactor is the financial saving on skip/container transportation costs.

Every time a skip/container is removed/exchanged there is a cost.

If for example you install a static compactor and obtain a 4:1 compaction ratio, you will reduce your skip/container transport costs by 75%.

With current average transport/exchange costs at around £150.00 per empty and assuming your skip with loose waste is currently emptied once a week, installing a static compactor would save you nearly £6000.00 per year in transportation costs.

As well as reducing transportation costs, having to process fewer skip transport/exchange invoices will save time on office administration as well.

Increased productivity

Another benefit of using a static waste compactor is that it can help increase your productivity. If you’re frequently transporting waste materials from one location to another, a static waste compactor can help you do so more quickly and efficiently.

Additionally, if you’re compacting materials on-site before disposal, it can help speed up the process and reduce the amount of time spent on manual labour.

Fewer exchanges not only benefit the site from fewer RO/RO vehicle visits to the premises, they also reduce office administration time due to the need to process fewer invoices.

Improved carbon footprint

Using a static waste compactor for waste management can be an effective way to make your company more environmentally friendly. Fewer waste material exchanges will benefit a company’s carbon footprint, making your business greener.

Versatility

Static compactors are very versatile and can be chosen to suit your business’s requirements.

One example is that they can be used for a variety of different waste materials. They are primarily used for general waste but certain compactors can also be used for soft plastics, metals and cardboard.

They are also available in a variety of sizes to suit the volumes of waste generated. You are able to choose a size that works best for your business in terms of how much space you have available as well as how much waste your company generates.

In addition, the waste can be fed in a variety of ways, by hand, tipper bin, or using an integrated bin lift for 1100 litre wheelie bins.

Static compactors can also be easily adapted to cater for air extraction and conveyor systems.

If you currently use a standard 26 cubic metre skip (35 cubic yard) you’ll find the overall height is 2.4 metres. If you’re not using steps, then it’s difficult to gauge where the waste has been loaded into the skip, so there may well be voids created meaning your skip could only be half full. If you do use steps, then these could be a health and safety issue if they’re wet, or if some of the waste streams are bulky, then this could also create a problem carrying the waste up the steps.

With a static compactor, the feed aperture is much lower making it far easier and quicker to load the waste and the compactor will ensure the skip is 100% full.

When is a Static Compactor Better Than a Portable?

As you can see, there are many benefits to using a static compactor. If your business produces a lot of waste or recyclables, investing in a compactor could help save you time and money in the long run, but how do you know whether a static waste compactor will be more suitable than a portable one?

Here are some of the advantages static waste compactors have over portable waste compactors:

- More efficient

- More customisable

- Best for large scale operations

More efficient

First and foremost, a static waste compactor is more efficient.

Unlike portable compactors, which require a motor to operate, static compactors are powered pneumatically or hydraulically, meaning they don’t need to use as much energy to run. This makes them more reliable than portable models and helps cut down on operating costs.

More customisable

Static compactors are also more easily customisable than portable compactors.

Most models come with multiple trays, chutes and conveyor systems that can be configured to suit your specific needs. Static compactors can either be supplied with an integrated bin lift which is fitted at the time of manufacture, or with an external bin lift.

And since static compactors are usually mounted in one place, it’s easier to access and maintain compared to a portable compactor.

Best for larger scale operations

Finally, static compactors are better suited for large-scale operations. They have higher compaction force, meaning they can handle larger loads than portable models.

And since they’re usually installed in permanent locations, they don’t need to be moved around as often, making them an ideal choice for businesses that generate and process large amounts of waste.

If you’re sold on the benefits of getting a compactor and want one that can handle large amounts of waste as well as being easy to customise and maintain, then a static compactor may be the right choice for your business. When businesses produce waste in large volumes, a static waste compactor makes waste management easier and more cost-effective.

Why not get in touch with us at Kenburn today to find out more about our range of static compactors and how they could benefit your business?