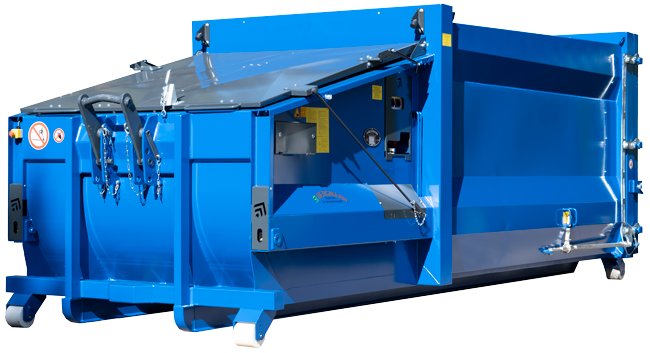

Portable Compactors

-

- Huge loading aperture

- Bin with pendulum roof for trouble-free emptying

- High compaction force due to linear arrangement of cylinders

- Press plate guiding system with 100% compaction force over the full stroke length

- Laterally fastened door with 3 central locks via easy-to-serve ratchet catch

- Pendulum claws on the break edge and the large immersion depth of the compacting piston avoid that the waste streams backwards

-

- Smaller Portable Compactor, transported via skip lift (chain lift)

- Container capacity ranges from 8-12m³

- Can be supplied with an integrated bin lift if required

-

- A larger machine which transported via a roll-on/roll-off (hook lift) vehicle

- Container capacity ranges from 14-20m³

- Can be supplied with an integrated bin lift if required.

NEED ASSISTANCE?

Benefits of Portable Compactors

Portable Compactors stand out thanks to their unique design and functional superiority. Traditional compaction machines often struggle with the efficient emptying of highly compacted materials like cardboard and plastics. Bergmann Compactors, however, have revolutionised this process, ensuring that even the most compacted materials can be easily removed.

A key feature of these compactors is the patented throw-over blade system. This innovative design eliminates the need for cleaning below or behind the blade, a common issue with traditional compactors. This not only saves time but also enhances the overall hygiene and maintenance of the compactor.

Our Compactors come in various sizes and formats, with container capacities ranging from 14-20m³. This range ensures that there is a perfect fit for different operational scales, from small businesses to large industrial setups. Certain models for example, feature a pendulum roof which swings upwards when the discharge door is opened, facilitating the effortless removal of highly compacted material.

All of our Portable Compactor range are made with quality in mind, designed and built to last.

What sets Bergmann Portable Compactors apart is their blend of high compaction efficiency and ease of emptying. The compactors are specifically designed to handle waste materials that are typically challenging to compact and dispose of. This makes them an ideal choice for businesses looking to improve their waste management practices, ensuring a cleaner, more efficient, and hassle-free process.

Portable Compactors offer a sophisticated solution to waste management challenges. Their innovative design, high compaction capability, and ease of emptying make them a valuable asset for any business seeking to enhance its waste disposal system. Explore our range of Portable Compactors and take a step towards more efficient, effective, and effortless waste management.

Not sure if a portable waste compactor is the right solution for you? Our experienced and knowledgeable team are always happy to discuss your requirements and advise on the best options for you. We also offer both purchase and rental options, so whatever your needs we will likely have a suitable solution.

BRANDS WE STOCK