Technical Info

Key Features of the Wire Tying System

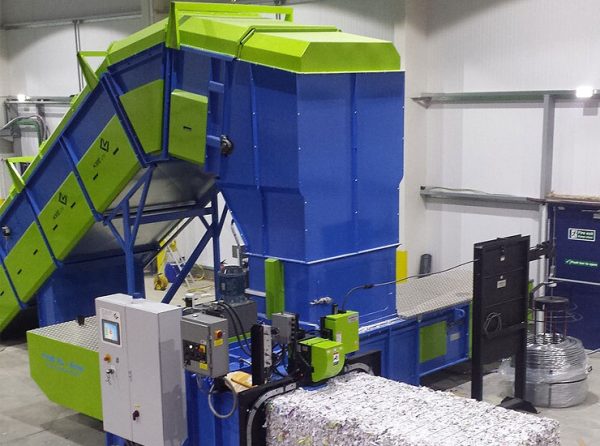

The Accent 470 wire tying system is an industry standard for twin ram wire tying systems. It can be programmed to put as many ties around the bale as required dependant on the material being baled.

- Pivot out spreader bar for servicing wear parts

- Four-wheel drive design

- Cycle time of under 3 seconds

- Tilt up knotter cover for daily maintenance

- All proximity switches

- Four twist knotter joint for added strength

- Multiple sides on cutter inserts

Additional Info

Colour Touchscreen

These fully automatic balers are controlled via a large colour touchscreen. It’s easy to control and make adjustments such as:

- Number of wires / straps per bale

- Position of wires / straps

- Main ram pressure

- Auto / manual operation

- Start / Stop feed conveyor

- Bale counter

The main motor capacity, hopper size, ram pressure and bale size can be changed to suit customer requirements.

An infeed conveyor can be designed and manufactured to suit the layout of the machinery and customer requirements.

Hardox wear plates for the press and eject chambers are fitted on all models.

Six large retaining clappers within the baling chamber increase the hopper fill between ram pushed thus increasing the capacity of the waste baler machines.

The number of wires can be selected to suit materials being processed.

NB. Production rates vary depending on the loose density of materials and the speed of operators. Bale weights are approximate and vary according to materials and material density.