Additional Info

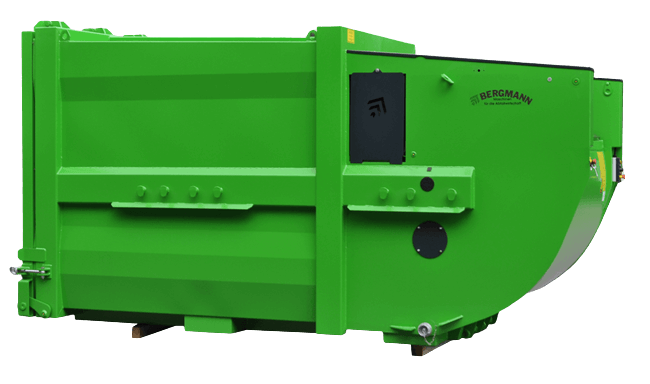

The equipment is suitable for continuous filling by conveyor belts or chutes and having a small footprint is easily located.

Once the machine is full, the waste is emptied by removing the sacks of waste on a pallet.

Key features of the PS 8100

- collects, shreds and compacts the waste by a specially equipped steel drum, which enables a compaction rate of up to 9:1

- compacts through an alternating right / left rotation of the special drum that constantly keeps the waste under pressure.

- allows for a continuous filling – the filler chute can also remain open during the work process.

- compacts waste in a transparent PE bag

- PS 8100 can be installed conveniently close to where waste is produced.

- ideally suitable for continuous filling through chutes or conveyor belts

- easy to operate.

- machine CE-certified

- durable and low maintenance

Hydraulically driven PS 8100 compacts into 1000 litre bags

The PS 8100 is particularly suited for packing foils, styropor (EPS), fruit boxes, cans, paper and cardboard as well as general refuse.

The results are spectacular!

Standard equipment

- Special compaction drum for paper and cardboard boxes

- Faceplate

- Electrical protection class

- Branded hydraulic pump.

- Autotimer

- Working hour counter

- Oil level monitoring

- Overload protection

- Pre-installed for the mounting of a pointed roof

Accessories

- Filler chute, reduction of filling height to 1,480 mm

- Folding door with automatic door opening

- Special compaction drum with blade set for various films.

- Cone roller with 24 cones for strong pasteboards

- Pointed roof constructed from glass fibre reinforced plastic.

- Full message via horn or flashing light

- sprinkler system

Ozone generator against unpleasant odours