Horizontal Balers

Our semi-automatic and fully automatic horizontal balers offer a robust solution for businesses generating more than 2 tonnes of waste material per day.

Proudly designed and manufactured in the UK our balers are the epitome of efficiency and quality.

-

KH40 Semi-Automatic Horizontal Baler

View MoreWidth

800 Height

1050 Depth

1200Bale Weight 300 to 350 kg

1 YR Warranty

The KH40 is a very versatile semi-automatic horizontal baler that can process the following type of materials: plastic film, plastic bottles, loose fluffy fibre type products, aluminium cans and steel cans.Depending on…Balers View More -

KH50 Semi Automatic Horizontal Baler

View MoreWidth

1000 Height

1070 Depth

1250Bale Weight 150 – 600kg

Cycle Time 45s

1 YR Warranty

The KH50 semi-automatic horizontal baler produces high-density “Mill Size” bales of a wide range of materials including cardboard, paper / board trim, expanded foam, plastic bottles, aluminium / steel UBC’s /…Balers View More -

KH Twin Ram Fully Automatic Horizontal Waste Baler

View MoreWidth

780 Height

1150 Depth

1200Bale Weight 400 - 600kg

Cycle Time under 3 s

1 YR Warranty

The Kenburn Select twin ram fully automatic horizontal baler handles high volumes of a range of materials including cardboard, plastic bottles, UBC cans, paper trim, foam scraps, polythene sheeting and…Balers View More

NEED ASSISTANCE?

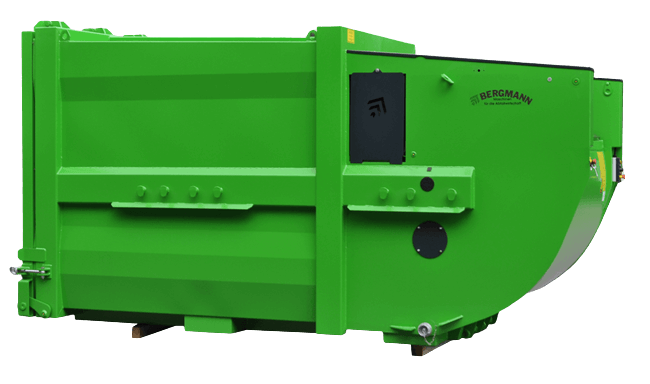

Types of Horizontal Balers

The semi-automatic variants require an operator to load materials and initiate the baling process. Once the bale reaches the desired size, the operator is prompted to tie off and eject the bale manually. For those seeking an even more streamlined process, the fully automatic horizontal balers come equipped with automatic wire tying systems, enhancing productivity and reducing manual labour.

Handling large volumes of waste can be a challenge for many organisations. If your operations produce over two tonnes of waste per day, Kenburn’s fully and semi-automatic horizontal balers are your go-to choice. While vertical balers might be more cost-effective for lesser volumes, nothing beats the efficiency of a horizontal baler when dealing with significant amounts.

Using a horizontal baler not only helps you to manage your waste more effectively, it also results in a clearer workspace and a reduction in transportation and waste collection costs. We offer a range of options depending on the amount of waste produced, but if you have any questions then please do get in touch.

High Quality Horizontal Waste Balers

The Kenburn Select Series balers are constructed with precision, adhering to the highest British quality standards. Our commitment to excellence ensures that every baler we offer is a reflection of our dedication to providing durable, efficient, and reliable waste management solutions.

Manufactured in the UK for Kenburn, these horizontal balers are the embodiment of top-tier British engineering – designed to keep your operations running smoothly while contributing positively to your company’s environmental and economic goals.

We are extremely proud that these balers are designed and manufactured in the UK.

We don’t only supply the machines, we also offer installation services, on-site training and ongoing maintenance support. So we like to see ourselves as your partner, helping you to get the very best from your machine. Looking after your horizontal baler with our support will ensure its longevity, saving your business money at the same time.

Not sure what you need? Our team are on hand to discuss your requirements and offer suggestions about which horizontal baler will be most suited to your needs.

BRANDS WE STOCK