Avermann Refurbished Machines

-

- Chain-Lift (skip lift) Compactor

- Capacity of 10 cubic metres

- Charge-box size of 1 cubic metre

- Feed-opening cover: Protects the feeding area i.e. from rain water or from filling by unauthorized people

- Round-up sealing on the rear-door and additional 4-point locking for a watertight discharging door

- Optional modem connection to send the filling degree and/or fault codes by SMS, language or e-mail to the waste disposal company

Avermann Compactors View More -

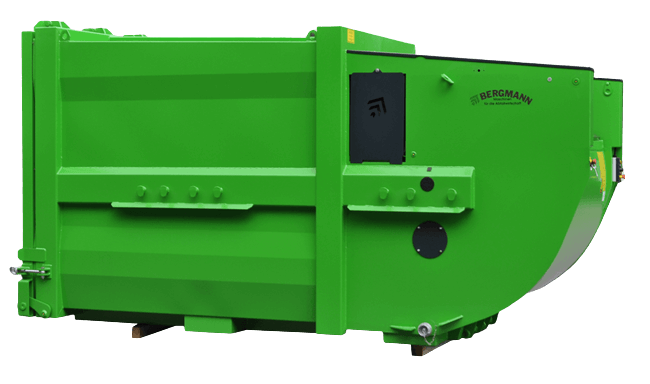

- Roll on / roll off (hook lift) Portable Compactor with a huge 20 cubic metre capacity

- Charge box size of 1.3 cubic metres.

- Optional ramp feeding, pendulum style rear door or side rear door

- Optional front or side feeding, slanted or high side walls and individual opening mechanisms

- Optional integrated bin lift

- Optional web based message system for location and filling level indication

Avermann Compactors View More -

- charge box size of 1 cubic metre

- cycle time of an amazing 34 seconds

Avermann Compactors View More -

- charge box capacity of 1.3 cubic metres

- cycle time of 47 seconds

Avermann Compactors View More

NEED ASSISTANCE?

Avermann Refurbished Balers and Compactors Key Benefits

Kenburn is proud to supply a selection of refurbished balers and compactors from Avermann, a renowned German manufacturer. These machines, first supplied by Kenburn in the 1990s, are known for their robustness and efficiency.

Our stock of Avermann refurbished machines is extensive and varied, including horizontal balers, conveyor systems, portable compactors, static compactors, and moveable external bin lifts. This diversity ensures that we can meet the unique requirements of different businesses, whether they need a compact solution for small spaces or a larger system for high-volume waste management.

Each Avermann machine undergoes a rigorous refurbishment process. Our experienced team ensures that every baler and compactor is restored to a high standard. They are cleaned, stripped down, re-sprayed, and have their component parts re-fitted or replaced as needed. This meticulous attention to detail guarantees that the refurbished equipment you receive from Kenburn is of the highest quality.

Avermann balers and compactors are renowned for their German engineering, synonymous with quality and reliability. When you invest in a refurbished Avermann machine from Kenburn, you are getting a product that combines these renowned engineering principles with the added value of our refurbishment expertise.

Flexible Options and Quality Products

Understanding that different businesses have different needs, Kenburn offers these refurbished Avermann machines for sale or rent. This flexibility allows you to choose the option that best suits your business’s financial and operational requirements.

All of our refurbished Avermann balers and compactors come with a limited twelve-month parts and labour warranty, provided they are maintained according to the manufacturer’s specifications. This warranty is a testament to our confidence in the quality of our refurbished machines and offers you peace of mind in your investment.

Choosing an Avermann refurbished baler or compactor from Kenburn means partnering with a company committed to providing high-quality, efficient waste management solutions. Whether you are looking to purchase or rent, our team is ready to assist you in selecting the best equipment for your needs, ensuring you benefit from our expertise and the exceptional quality of Avermann machinery.

Contact us to explore our range and find out how we can help enhance your waste management strategy.

BRANDS WE STOCK